$127.27

During part extraction on the Fuse Sift, unsintered powder is dislodged and funneled into the sifter below the workspace. This 150 µm sieve filters out any small chunks or debris to keep the powder clean. The reclaimed powder can then be stored in a dedicated hopper until mixing with fresh powder for the next print. Compatibility Printer compati...

$127.27

During part extraction on the Fuse Sift, unsintered powder is dislodged and funneled into the sifter below the workspace. This 300 µm sieve filters out chunks or debris to keep the powder clean, while allowing powder flow with Nylon 11 CF Powder. The reclaimed powder can then be stored in a dedicated hopper until mixing with fresh powder for the...

$70.07

The Fuse Parts Carrier is a container designed for powder-free part collection when used with the Fuse Sift. Simply slide it into the build chamber enclosure after part extraction to seamlessly transfer parts without opening the glovebox to maintain an enclosed environment and clean workstation.

$5,718.57

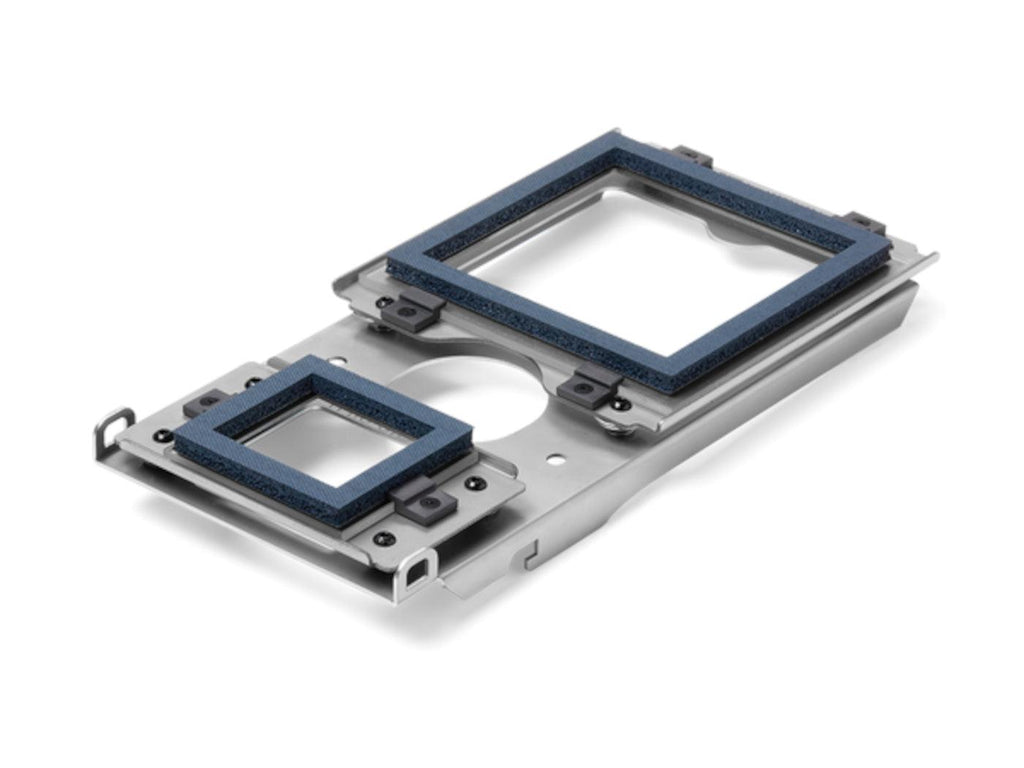

Reduce downtime by transferring modular build chambers and powder cartridges between the Fuse 1 generation printers and Fuse Sift for a nonstop, cyclical workflow. Each Fuse 1 generation printer includes one build chamber. Keeping an extra build chamber in your toolkit allows you to run a new print as soon as a previous job is completed. After c...

$78.65

The Fuse QT Heater ensures uniform heating of the printer bed. Sold individually. Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

$400.40

All selective laser sintering (SLS) printers require operators to clean the optics before every print, which often involves disassembling complex systems. The Fuse 1 protects its optics with an optical cassette designed for tool-free removal and installation. Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

$213.07

A HEPA filter is used in conjunction with the Fuse Sift air handling system to filter out powder. This enables the Fuse Sift to maintain negative pressure under the hood and minimizes potential mess in the workspace.

$114.40

The Fuse 1 uses an exhaust filter to remove sintering byproducts from its exhaust. Printer compatibility: Fuse 1, Fuse 1+ 30W Supplier code: EF-FS1-01

$171.60

Fuse 1 & Fuse 1+ Upper Laser Window Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

$21.45

What’s Included Build Chamber External Frame Gasket Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

$70.00

What’s Included Fuse Blast Polish System Preventative Maintenance Kit

$21.45

What’s Included Fuse Build Chamber Inner Gasket Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

Reduce downtime by transferring modular powder cartridges and build chambers between the Fuse 1(+) generation printer and Fuse Sift for a nonstop, cyclical workflow.

Use the powder cartridge to load material dispensed from the Fuse Sift, our powder recovery solution, into the Formlabs SLS 3D printer's hopper. The powder cartridge is also used as a mixing vessel when combining fresh and used powder.

Use Fuse Series Powder Cartridge with Fuse Sift for a seamless, automatized workflow for SLS 3D printing production.

Seamless Workflow

Slide the cartridge into your Fuse SLS printer or Fuse Sift to go from printing to powder recovery to mixing with ease thanks to the streamlined cyclical ecosystem.

Mess-Free Powder Handling

Use the Powder Cartridge to keep your work environment powder-free. The sliding opening allows you to keep the SLS material contained until released in the printer.

Powder Recovery Made Easy

Fuse Sift will dispense and mix the new and used powder in the cartridge and prepare the batch for your next print, so you can keep your hands off the powder.

Minimum Waste, Maximum ROI

Achieve low to zero-waste printing by recovering and re-using your unsintered powder easily and maximize your ROI.

1) Fill in the cartridge: SLS 3D printing allows you to print with reused powder to minimize your waste and reduce your costs. Insert the cartridge into Fuse Sift and choose your ratio of fresh/used powder. Fuse Sift automatically dispenses the used SLS powder recovered from your past prints and mixes it with fresh powder to fill the cartridge.

2) Mix the powder: take the full cartridge and slide it into the agitator on the side of the machine. Fuse Sift will tumble the powder cartridge to make sure all the powder is evenly mixed.

3) Fill the hopper: Slide the cartridge into the top of the hopper until it's securely inserted and the opening is sealed into the hopper. Pull the sliding opening to release the SLS powder into the hopper.

4) Print: Follow the instructions on the printer to start the print.

5) Powder recovery: When the print is done, insert the build chamber and an empty powder cartridge into Fuse Sift. Extract the parts from the powder cake with the help of the tools and vacuum - Fuse Sift will sift and collect the used powder as you do.

6) Done: Fill in a new cartridge for your next print.

Printer compatibility: Fuse 1, Fuse 1+ 30W

Material compatibility: Nylon 11, Nylon 11 CF, Nylon 12, Nylon 12 GF, TPU 90A