$5,003.47

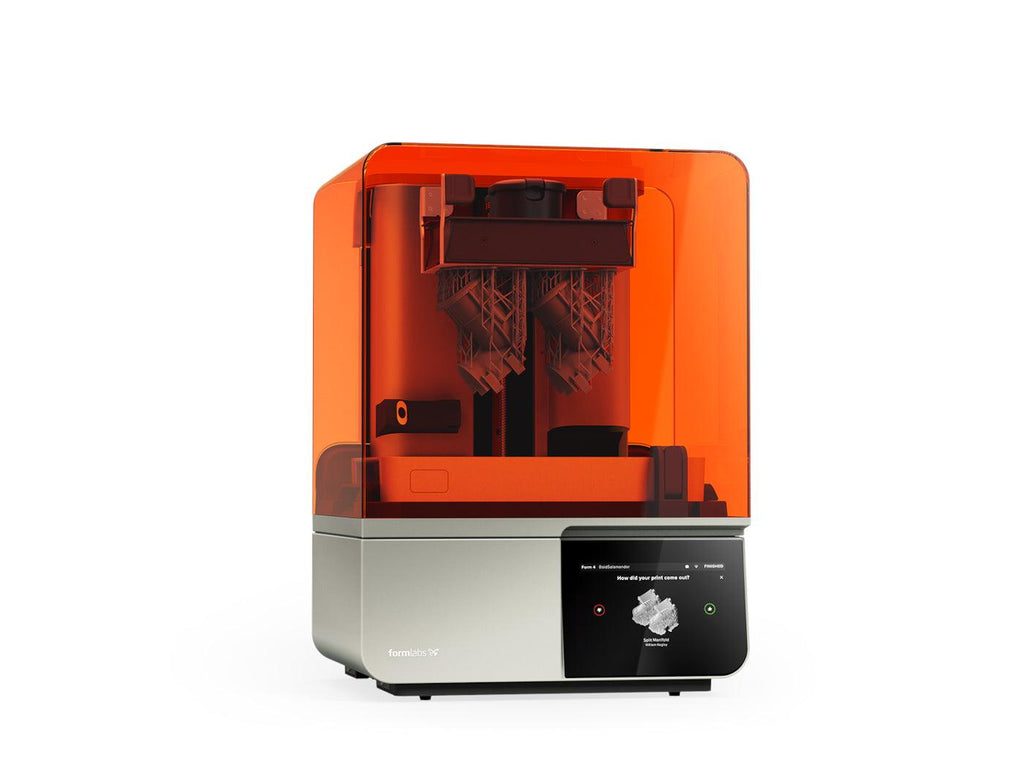

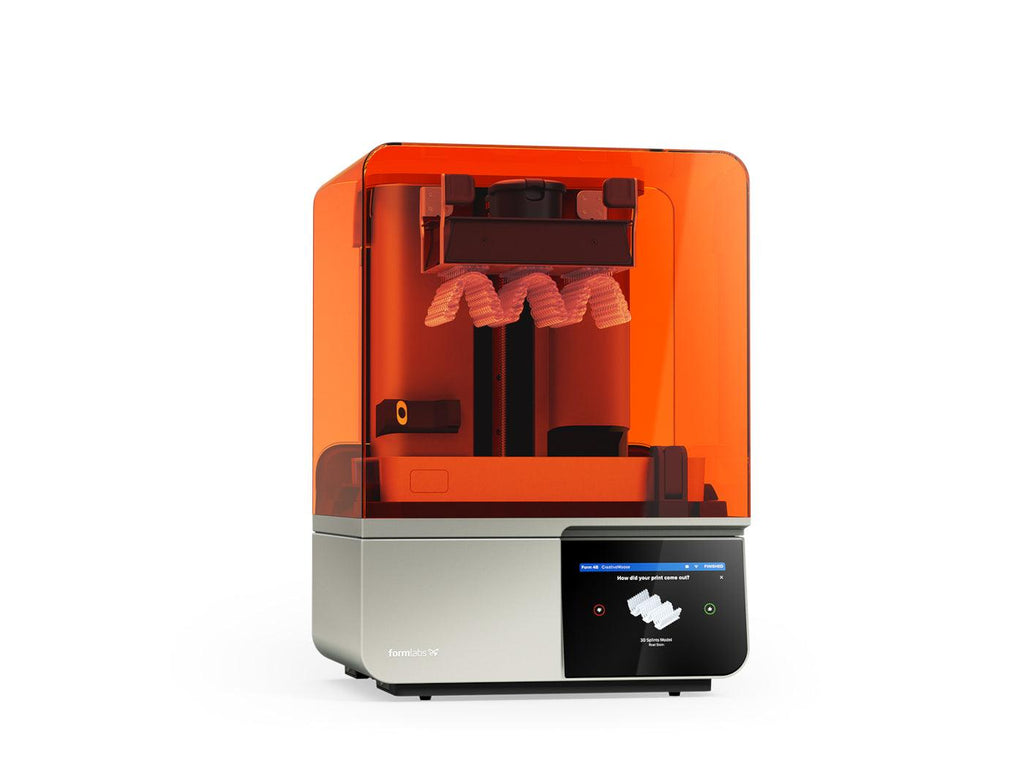

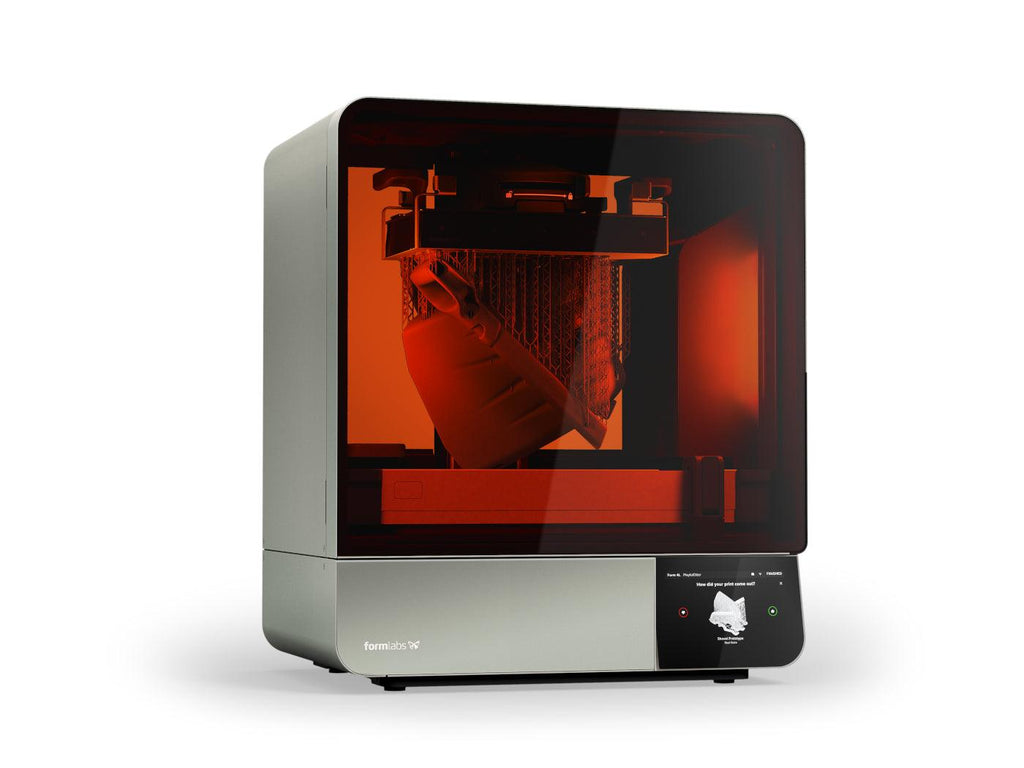

One of Voxel Factory favorite's release since years! Why? Faster: 3 to 5 times faster! Most prints finished in less than 2 hours. Reliable: Unmatched print success rate compared to previous & other systems. Versatile: All usual advanced materials, new models & cheaper standard resins. Intuitive: Top-notch Formlabs guides and documentat...

$8,537.11

One of Voxel Factory favorite's realese since years! Why? Faster: 3 to 5 times faster! Most prints finished in less than 2 hours. Reliable: Unmatched print success rate compared to previous & other systems. Versatile: All usual advanced materials, new models & cheaper standard resins. Intuitive: Top-notch Formlabs guides and documentat...

$999.57

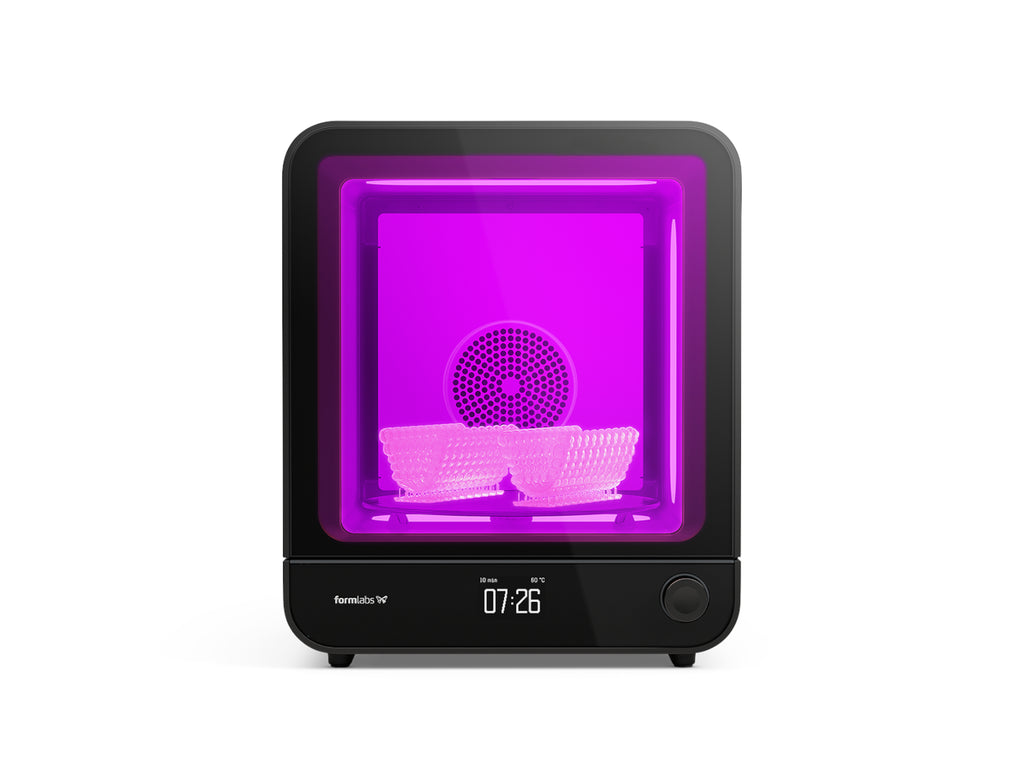

Form Wash automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook an...

$1,428.57

Form Cure (2nd Generation) precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure Form 4/B prints in as little as 60 seconds, with 4x more UV power, 5x faster heat-up times, and a 1.3x larger chamber. To begin curing, just select a validated preset for Formlabs 45...

$899.00 $1,072.50

Présentement en stock! Pour les meilleures performances dans le procédé de post-cure, avec une température contrôlée et une longueur d'onde précise de 504nm. 13 DEL multi-directionnelles émettent la lumière de longueur d'onde optimale pour la cure des matériaux de Formlabs. Les réflecteurs et le plateau rotatif permettent de s'assurer...

$14,298.57

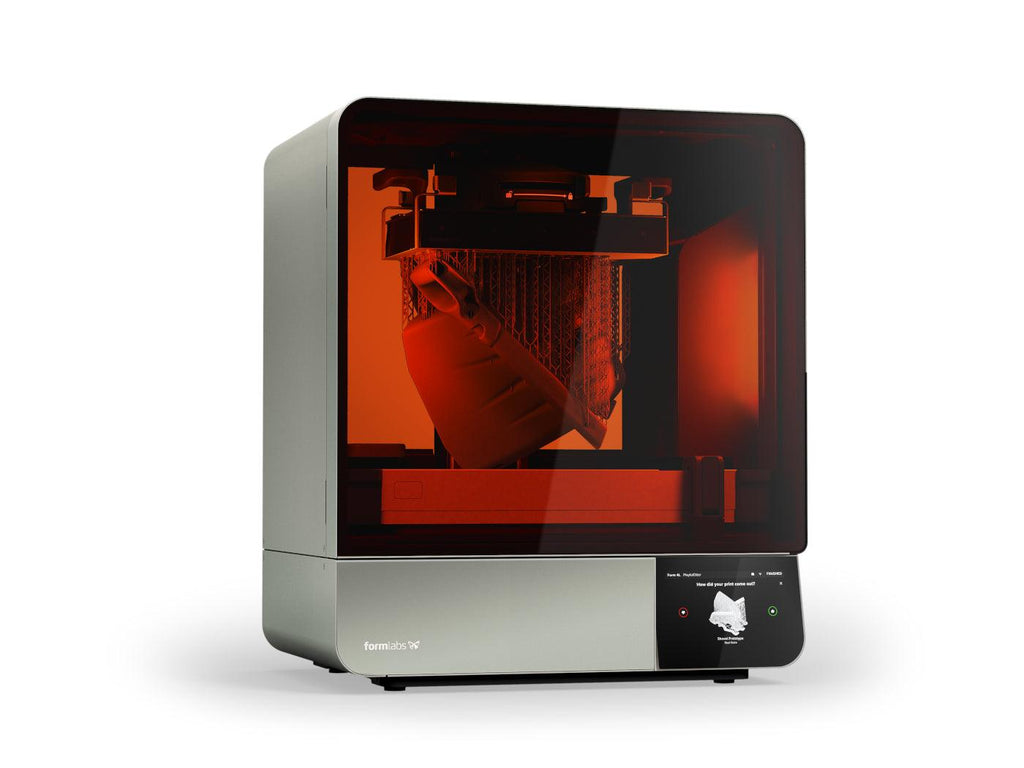

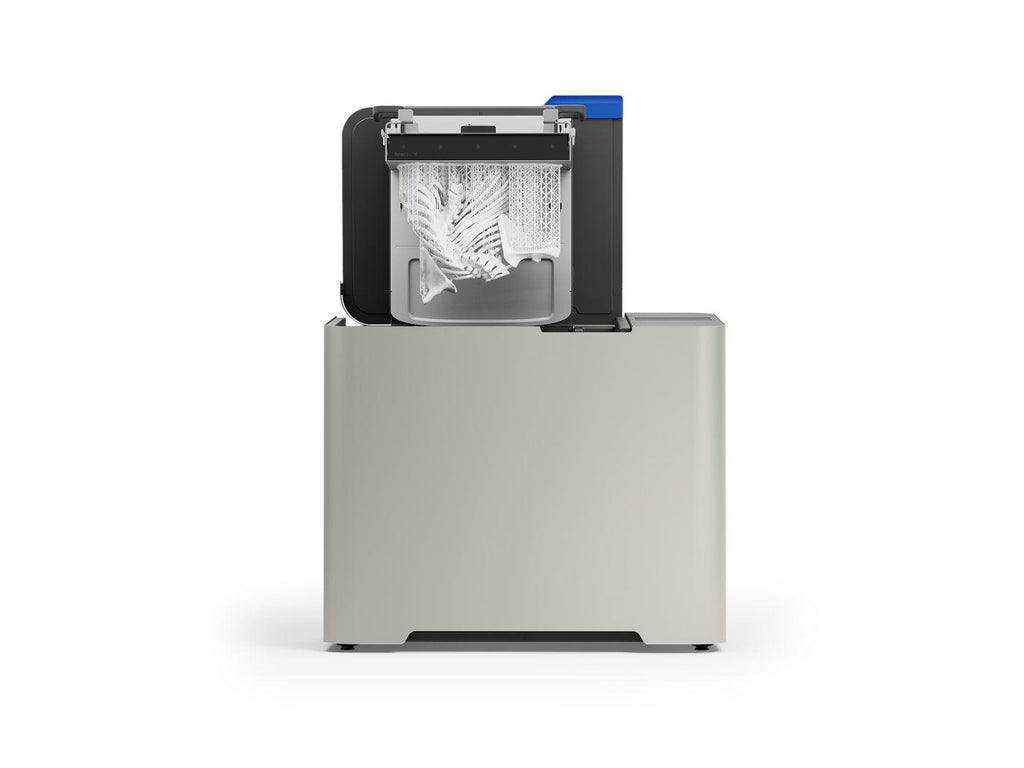

One of Voxel Factory favorite's release since years! Why? BIG PARTS: 4.6x larger build volume compared to Form 4. BLAZING FAST: Large prints in under 6 hours. VERSATILE: Industry-leading materials & Open Materials Mode INTUITIVE: Top-notch Formlabs guides and documentation. RELIABLE: Large format 3D printing you can depend on. STUNNING P...

$28,598.57

What’s Included 1 x Form 4L Printer 1 x Form 4L Resin Tank 1 x Form 4L Mixer 1 x Form 4L Build Platform L 1 x Resin Pump (Form 4) 1 x Form 4L Finish Kit: Cleaning Tools 1 x Form Wash L (2nd Generation) 1 x Form Cure L 120V 1 to 3 year Form 4L Pro Service Plan One of Voxel Factory favorite's release since years! Why? BIG PARTS: 4.6x larger bui...

$6,435.00

** Basic Warranty of 1 Year All SLA 3D printed parts require washing to remove residual resin. Form Wash L automates this process, leaving you with smooth, clean, high-quality parts every time. Once washing completes, parts are lifted out of the solvent to air dry, avoiding over-soaked, warped prints. The embedded solvent monitor helps you ma...

$6,435.00

** Basic Warranty of 1 Year Form Cure L V2 precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure large Form 4L/BL prints in as little as 60 seconds, with 5x more UV power, faster heat-up times, and a 26% reduction in overall footprint from the previous generation...

$6,435.00

Save time, minimize effort and maximize efficiency with the automated, large format post-processing Form Cure L machine. The Formlabs Form Cure L exposes 3D printed parts to the appropriate levels of light and heat to optimize material properties. It uses heat, UV light, and consistent universal exposure to bring parts to their peak mechanical ...

One of Voxel Factory favorite's release since years! Why?

Backlit Unit:

The Backlight Unit generates a uniform area projection of an ultra-high power light using 145 LEDs and collimating lenses. It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform.

Light Processing Unit:

The Light Processing Unit 4L (LPU 4L) precisely masks light from the backlight unit into the shape of a printed layer. Together, the Backlight Unit and LPU 4L enable you to print with extreme speed, accuracy, and print quality anywhere on the build platform. The LPU 4L is long -lasting, resistant to accidental damage, and easy to replace.

Release texture:

A proprietary, microtextured optical film provides airflow between the resin tank and the Light Processing Unit. This film is built into the Light Processing Unit and sits at the top of it. This significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

Intelligent Control System:

Six onboard control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer. Together, they ensure consistent, reliable performance and prevent common failures, for the same results on every printer and every print.

Resin Tank:

The Form 4L Resin Tank holds liquid resin inside the printer and provides a substrate for the liquid resin to cure against, using a dual-layer flexible film stack. It significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

Automatic Resin Handling:

Integrated system that dispenses resin quickly, accurately, and with minimal waste, while making it easy to switch materials. Print without having to worry about your printer running out of resin and switch materials in <1 minute. Form 4L is still one of the only SLA printers on the market to offer this feature.

Looking to print with biocompatible materials? See Form 4BL.

Technology

Masked Stereolithography (MSLA)

Printer Engine

Low Force Display™ (LFD)

Key Components of the Print Engine

Backlight Unit

Light Processing Unit 4L (LPU 4L)

Release Texture

Flexible Film Resin Tank

Intelligent Control Systems

Automatic Resin Handling

Light Source

Backlight Unit: 145 uniform-wavelength LEDs, a plano-convex lens array, and integrated air cooling

405 nm optical wavelength

16 mW/cm² optical power intensity delivered to the cure plane

46 µm pixel size

Maximum Print Speed¹

80 mm/hr

3.1 in/hour

Typical Print Speed²

Average: 24 mm/hour (0.9 in/hour) across all materials

Range: 20-35 mm/hour (0.8-1.4 in/hour) depending on material

Typical Dimensional Tolerances³

1-30 mm features: ±0.15% (lower limit: ±0.02 mm)

31-80 mm features: ±0.3% (lower limit: ±0.06 mm)

81-150 mm features: ±0.3% (lower limit: ±0.15 mm)

Surface Accuracy (Restorative Models)⁴

On average with Precision Model Resin:

99.9% of surfaces within 100 μm of CAD model

96.7% of surfaces within 50 μm of CAD model

71.4% of surfaces within 25 μm of CAD model

Materials

19 industry-leading Formlabs materials or third-party materials using Open Material Mode. More exciting new materials are currently in development.

Explore Materials

Biocompatible Materials

YES

Build Volume (W x D x H)⁵

35.3 × 19.6 × 35.0 cm

13.9 x 7.7 x 13.8 in

24.2 liters

Build Area

692 cm²

107 in²

Maximum Part Length⁶

Not measured

XY Resolution⁷

46 µm with pre-tuned anti-aliasing for subpixel resolution

Superior fine feature performance and sharp features compared to the Form 3L Series

Layer Thickness⁸

25–200 µm

0.001–0.008 in

Resin Cartridges

2

Resin Cartridge Type

Next-generation resin cartridge

5-10x faster filling

63% less waste

30% less shelf space

Resin Heating

High speed conduction resin heating with infrared temperature sensing

Internal Temperature

Auto-heats resin to 25–45 °C (77–113 °F), depending on material

Force Sensing

Z-Axis Force Sensor, automatically optimizes print quality and print speed based on part geometry and selected material.

Supports

Auto-generated

Light-touch removal

Design/CAD Specifications

Printer Dimensions (W x D x H)

66.4 x 52.8 x 79.4 cm

26.1 x 20.8 x 31.3 in

Minimum Access Dimensions (W x D x H)

88.9 x 116.9 x 81.3 cm

35 x 46 x 32 in

Printer Weight

58.5 kg

129 lb

Operating Environment

18–28 °C

64–82 °F

Power Requirements

100-240 VAC

9 A

50/60 Hz

900 W

Connectivity

Wi-Fi (2.4 and 5 GHz; IEEE 802.11 b/g/n/ac, WPA/WPA2)

Ethernet (1000 Mbit)

USB-C 2.0

Printer Control⁹

7" interactive touchscreen

1280 × 800 resolution

Languages: English, German, French, Spanish, Italian, Japanese, Simplified Chinese

Alerts

Touchscreen alerts

SMS/email via Dashboard

Speaker for audio alerts

Sensors and Control Systems

6 upgraded sensors that precisely control resin temperature, resin level, print forces, and print status:

High-speed conduction resin heating with infrared temperature sensing

Ultrasonic Resin Level Sense: controls resin in the tank

Z-Axis Force Sensor: controls and minimizes print forces

Resin Cartridge Load Cell: measures exact resin level in cartridge

Printer Leveling Sensor

Camera

Camera

Integrated camera

2592 x 1944 resolution (5MP)

Remote monitoring, print history, and print timelapses

Can be easily disabled, covered, or removed

Software

PreForm System Requirements

Windows 7 (64-bit only, ARM not supported) and up

Mac OS X 10.15 and up

OpenGL 2.1

C++ runtime library from Microsoft (Windows only)

4 GB RAM (8 GB recommended)

PreForm File Types

STL, OBJ, and 3MF file input

FORM file output

PreForm Print Setup Features

One-Click Print

Adaptive layer thickness for faster printing with fine details

Remote Print

Auto-orient for optimal print position

Auto-mesh repair

Auto-generation of supports

Manual editing of supports

Rotate, scale, duplicate, and mirror

Layer slicer for path inspection

Custom print settings

Available in multiple languages

Dashboard Printer Management Features

Manage prints and printers via the cloud

Track resin and tank usage over time

SMS and email alerts

Create enterprise group accounts with admins to more easily share printers and control access

Resin Tank Estimated Lifetime¹⁰

75,000+ layers with any Formlabs material

For example: approximately 190 prints using an average height model (39 mm tall), any resin, and 100 µm layer height

Light Processing Unit Estimated Lifetime¹¹

600k - 1.9M layers, depending on material and layer height

For example: approximately 1,300 prints using average height models (87 mm tall), Grey Resin V5, and 100 µm layer height