- Home

- Formlabs Form 4BL 3D printer Basic Package

Formlabs Form 4BL 3D printer Basic Package

Related Products

Original Prusa MK4S DIY kit

$999.00

Fast and Precise Results without Compromise The Original Prusa MK4S delivers reliable results for all your projects. Building on the MK4 model loved by hobbyists and big companies alike, it offers even higher accuracy and print speed. Thanks to its new 360° cooling, high-flow nozzle, and numerous firmware optimizations, you’ll get your 3D mode...

Prusa CORE One

$1,699.00

Whether you're new to 3D printing or a seasoned expert, Prusa CORE One ticks all the boxes for a reliable all-around machine. Featuring an enclosed chamber and CoreXY design, it combines high-speed printing and maximum print quality with a large 250×220×270mm print area. And there are plenty of clever design choices, e.g., an all-steel exoskelet...

Original Prusa XL

$4,299.00

The Original Prusa XL is the most innovative 3D printer on the market, offering possibilities that no single-nozzle multi-material printer can replicate. With a state-of-the-art five-head tool changer, top print quality, extreme precision, huge print volume, and zero-waste printing, the Original Prusa XL establishes a new category for itself. Fe...

Prusa Pro HT90

$13,999.00

The Prusa Pro HT90 is a delta kinematics 3D printer with a cylindrical print area (Ø300 × 400 mm). It is specifically designed to maximize the potential of advanced materials like ABS, ASA, PCCF and PA. Its heated chamber, which reaches up to 90 °C, and innovative cooling system, provide unparalleled layer adhesion and print quality. With the HT...

Bambu Lab H2D Pro 3D Printer

$5,099.00

** The filaments in the pictures are sold separately. Key Features compared to H2D Network Support: Includes wired networking and enterprise network authentication. Tungsten Carbide Hotend: Offers increased durability and precision. Enhanced Toolhead Cooling: Upgraded fan system for improved thermal management. Additional Components:...

Bambu Lab H2D 3D Printer

$2,599.00

Bambu Lab H2D Rethink Personal Manufacturing Rethink Personal Manufacturing Ton navigateur ne prend pas en charge la vidéo HTML5. Specs Item Specification Printing Technology Fused Deposition Modeling Build Volume (W×D×H) Single Nozzle: 325×320×325 mmDual Nozzle: 300×320×325 mmTotal Volume for Two Nozzles:...

Bambu Lab H2D Laser Full Combo

$3,799.00

Explore Dual-Nozzle Capabilities Multi-material Printing Flexible and rigid, low cost and exotic materials in one print Combine flexible and rigid materials in a single print to create impressive interlocking structures and innovative designs beyond traditional manufacturing. Pairing high-performance materials with standard ones further reduc...

Bambu Lab H2S 3D Printer

$1,649.00

340*320*340 mm³ Print Volume Multi-color 3D Printing Closed-loop Servo Motor Extruder Optional 10W Laser and Cutting Module 5μm Resolution Optical Motion Calibration 350°C Nozzle & 65°C Active Chamber Heating Full Filament Path AI Detection Voltage Range: 100-120 V Specs Item Specification Printing Technology Fused Deposition Mode...

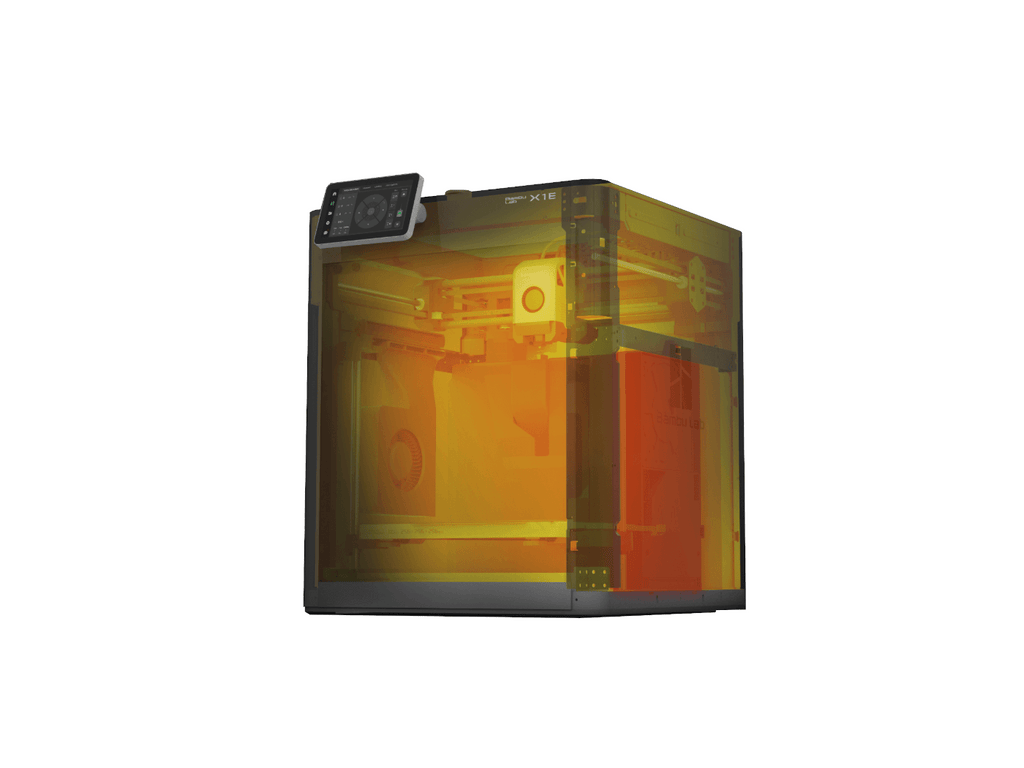

Bambu Lab X1E Combo with AMS

$3,199.00

What to Expect from the X1E 3D Printer Automatic Material System (AMS) INCLUDED Up to 16 multi-color printing with 4 AMS (Sold separately) Dual auto bed leveling 7μm lidar resolution Spaghetti failure detection AI inspected first layer Upgrades compared to X1C Ethernet port WPA2-Enterprise Wi-Fi Authentication (EAP-PEAP/EAP-TLS/TAP-TTLS) Ph...

Makerbot Method X Carbon Fiber

$6,999.00 $9,395.00

Ask For Quote 3 hours of free training at Voxel Factory. CARBON FIBER MADE ACCESSIBLE Replace metal parts and assemblies with 3D printed Carbon Fiber and dissolvable supports DUAL EXTRUSION COMPOSITE 3D PRINTING FOR ADVANCED GEOMETRIES Patented VECT™ 110 (Variable Environmental Controlled Temperature) Thermal Regulation evenly heats and...

Makerbot Method XL

$20,236.95

Ask For Quote 3 hours of free training at Voxel Factory. UltiMaker Method XL 3D print large-scale projects with industrial-grade materials. Scale up your 3D printing output with the Method XL. Larger parts, increased output, and competitive pricing. Experience the precision of industrial production alongside the flexibility of a 3D printer...

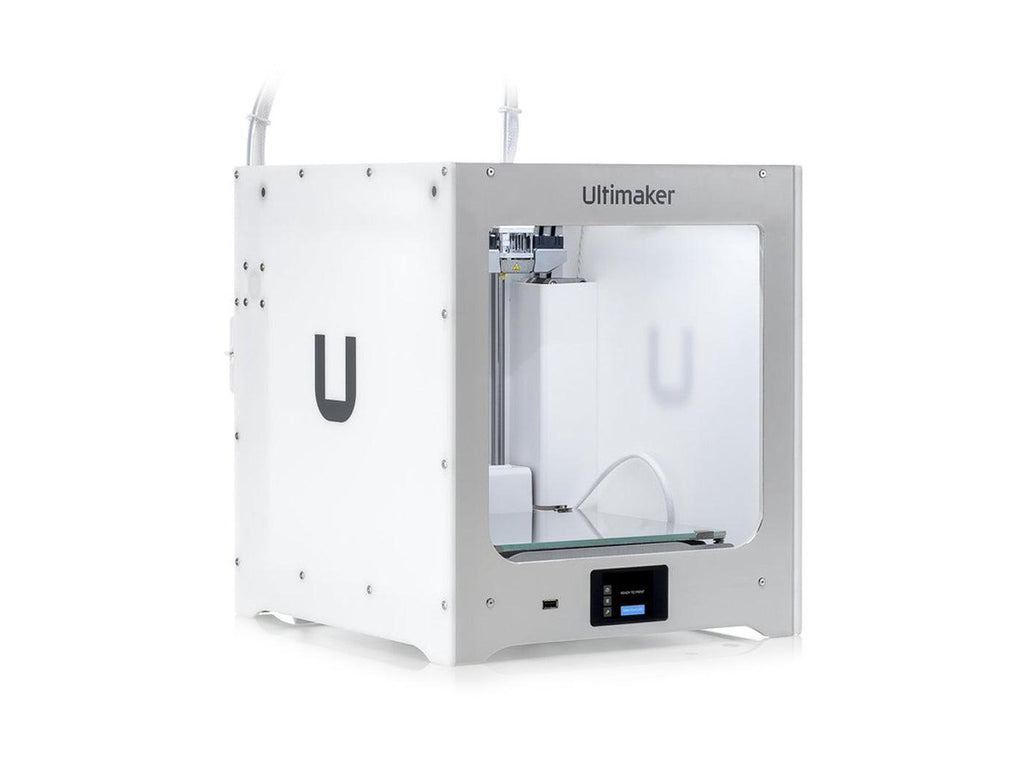

Ultimaker 2+ Connect Single nozzle 3D printer

$3,499.00 $3,795.00

The newest addition to Ultimaker's line of FFF printers, The Ultimaker 2+ Connect. A single nozzle printer with networking capabilities and a new touchscreen, the Ultimaker 2+ Connect is your reliable first step into our world of easy, remote 3D printing. Simply unbox and connect three components, and get started. This speedy setup even makes i...