- Home

- Newest Products

- Flexible 80A Resin 1L (Form 4)

Flexible 80A Resin 1L (Form 4)

Related Products

Original Prusa MK4S 3D Printer kit

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$999.00

Fast and Precise Results without Compromise The Original Prusa MK4S delivers reliable results for all your projects. Building on the MK4 model loved by hobbyists and big companies alike, it offers even higher accuracy and print speed. Thanks to its new 360° cooling, high-flow nozzle, and numerous firmware optimizations, you’ll get your 3D models...

PC Blend Carbon Fiber Black 800g

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$83.99

What can you expect? Prusament PC Blend Carbon Fiber (PCCF) is our own in-house made filament filled with carbon fibers. The whole manufacturing process is closely monitored and tested - we guarantee ±0.04 mm precision and highly-consistent colors. You can inspect the parameters of every spool we made at prusament.com. Check the sample sp...

Prusament PC Blend 1.75mm

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$69.99

What can you expect? Prusament PC Blend is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.03mm precision and highly-consistent colors. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool! Manufactured In-House By Jose...

PETG Tungsten 75% 1kg

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$320.60

What can you expect? Prusament PETG is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.02mm precision and highly-consistent colors. You can inspect parameters of every spool we made at prusament.com. Check the sample spool! Manufactured In-House By Josef Prusa We...

Prusament PETG 1.75mm

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$40.60

What can you expect? Prusament PETG is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.02mm precision and highly-consistent colors. You can inspect parameters of every spool we made at prusament.com. Check the sample spool! Manufactured In-House By Josef Prusa We...

Prusament PLA 1.75mm

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$40.60

What can you expect? Prusament PLA is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.02mm precision (± 0,03 for blends) and highly-consistent colors. You can inspect parameters of every spool we made at prusament.com. Check the sample spool! Manufactured In-Hous...

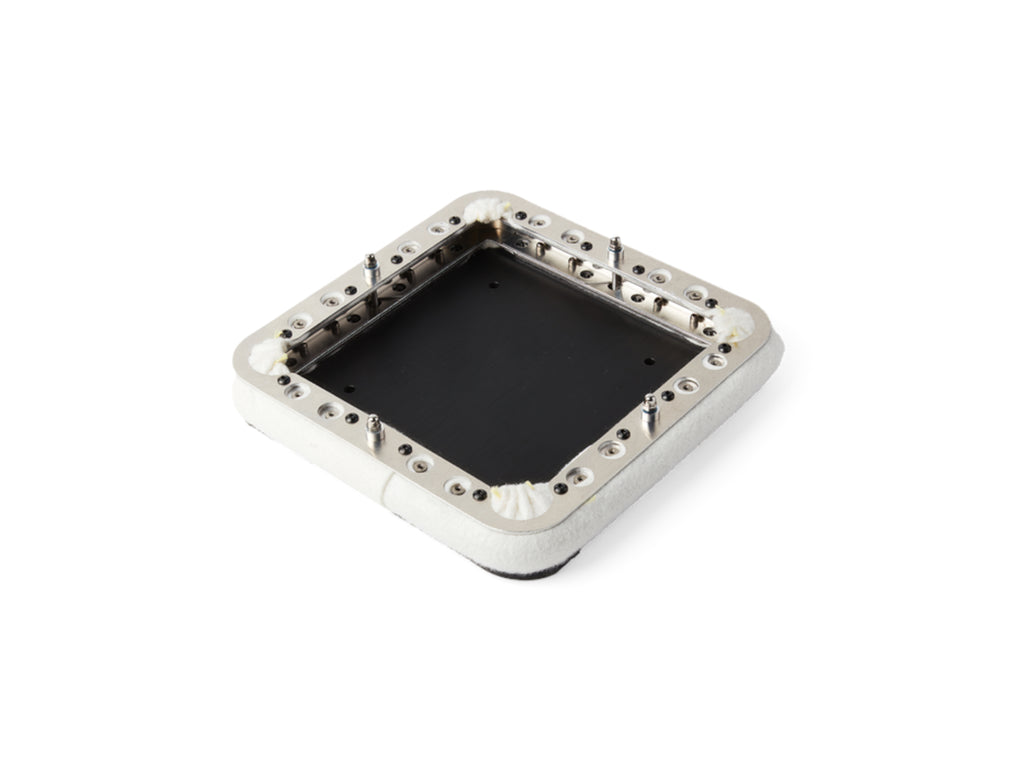

Fuse 1 Print Bed Assembly

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$293.15

Replacement print bed assembly for the Fuse 1 Build Chamber. Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W

Dental LT Clear Resin 1L (Form 4)

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$499.07

Dental LT Clear Resin V2 is a long-term biocompatible material for directly printing affordable, high-quality hard splints and occlusal guards in-house. Highly durable and resistant to fracture, this color-corrected material prints clear, polishes to high optical transparency, and resists discoloration over time.Read our Application Guide to lea...

White V5 Resin 5 L (Form 4)

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$464.75

White Resin V5 is an exceptionally bright white General Purpose Resin, offering an optimal balance of fast print speed, high accuracy, presentation-ready appearance, strong mechanical properties, and an easy, reliable workflow. Create parts that are stiff and strong with a surface finish that rivals injection molding. White Resin has a bright, m...

Castable Wax Resin 1L (Form 4)

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$410.00

Castable Wax Resin is a 20% wax-filled material for casting that can capture intricate features and offers a smooth surface finish for accurate castings with zero ash content and clean burnout. It is ideal for ultrafine structures in jewelry, as well as highly accurate patterns for casting and pressing dental prosthetics.For dental: Castable Wax...

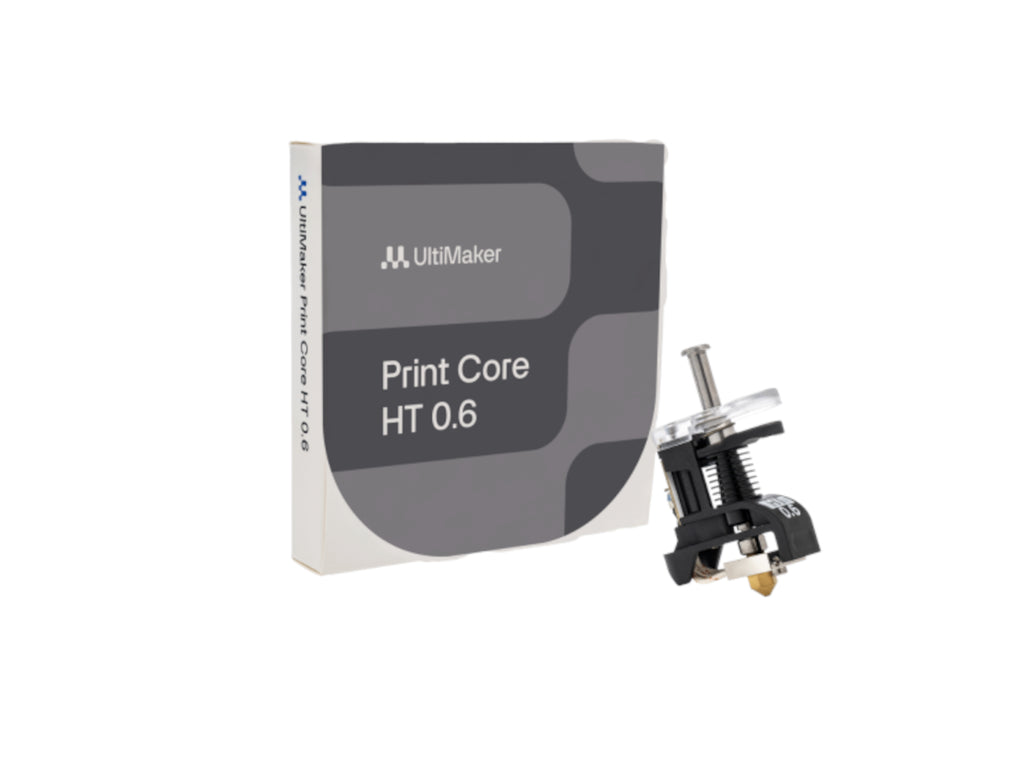

UltiMaker Print Core HT 0.60mm

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$499.07

Replacing the Print core HT 0.60mm This print core is specifically engineered for PPS CF material on the Factor 4 3D printer. Only compatible with the Ultimaker Factor 4 Manufacturer : UltimakerNozzle size : 0.6mm

Fuse Build Chamber Inner Gasket

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$15.00

What’s Included Fuse Build Chamber Inner Gasket Compatibility Printer compatibility: Fuse 1, Fuse 1+ 30W