- Home

- Newest Products

- Polymaker Fiberon PETG-ESD 1.75mm 500g

Polymaker Fiberon PETG-ESD 1.75mm 500g

Related Products

Polymaker Fiberon PA612-ESD 1.75mm 500g

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$88.99

Print Industrial-Grade ESD Parts with Polymaker™ Fiberon PA612-ESDEngineered for professionals who need performance where it counts. With built-in ESD safety, carbon fiber reinforcement, and high thermal stability, this nylon filament is your go-to material for demanding electronic and manufacturing applications. ESD-Safe and Ready for ActionWit...

Polymaker Fiberon PPS-GF20 1.75mm 500g

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$81.99

Print Electrically Insulative, Flame-Retardant Parts with Fiberon™ PPS-GF20Designed for engineers who demand the best in thermal resistance, dimensional stability, and dielectric insulation. This glass fiber–reinforced PPS filament is the go-to choice for high-performance applications across electronics, aerospace, and industrial environments. I...

Bambu Lab H2D Pro 3D Printer

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$5,099.00

Key Features compared to H2D Network Support: Includes wired networking and enterprise network authentication. Tungsten Carbide Hotend: Offers increased durability and precision. Enhanced Toolhead Cooling: Upgraded fan system for improved thermal management. Additional Components: Now includes the AMS HT and visual coding board. Expanded ...

Original Prusa XL Enclosure

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$909.00

Seamless Integration The XL Enclosure is designed for seamless integration with the rest of the printer. Not just the physical parts, but also the software: because the Enclosure is directly connected to the mainboard of the printer, you can configure a number of useful functions directly through the printer’s LCD touch panel. Set up the filt...

Prusa Pro HT90

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$13,999.00

The Prusa Pro HT90 is a delta kinematics 3D printer with a cylindrical print area (Ø300 × 400 mm). It is specifically designed to maximize the potential of advanced materials like ABS, ASA, PCCF and PA. Its heated chamber, which reaches up to 90 °C, and innovative cooling system, provide unparalleled layer adhesion and print quality. With the HT...

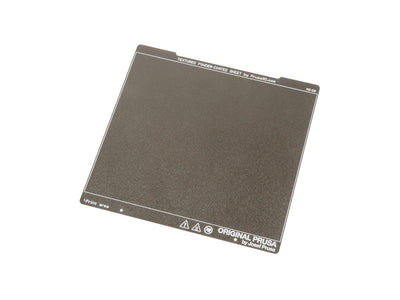

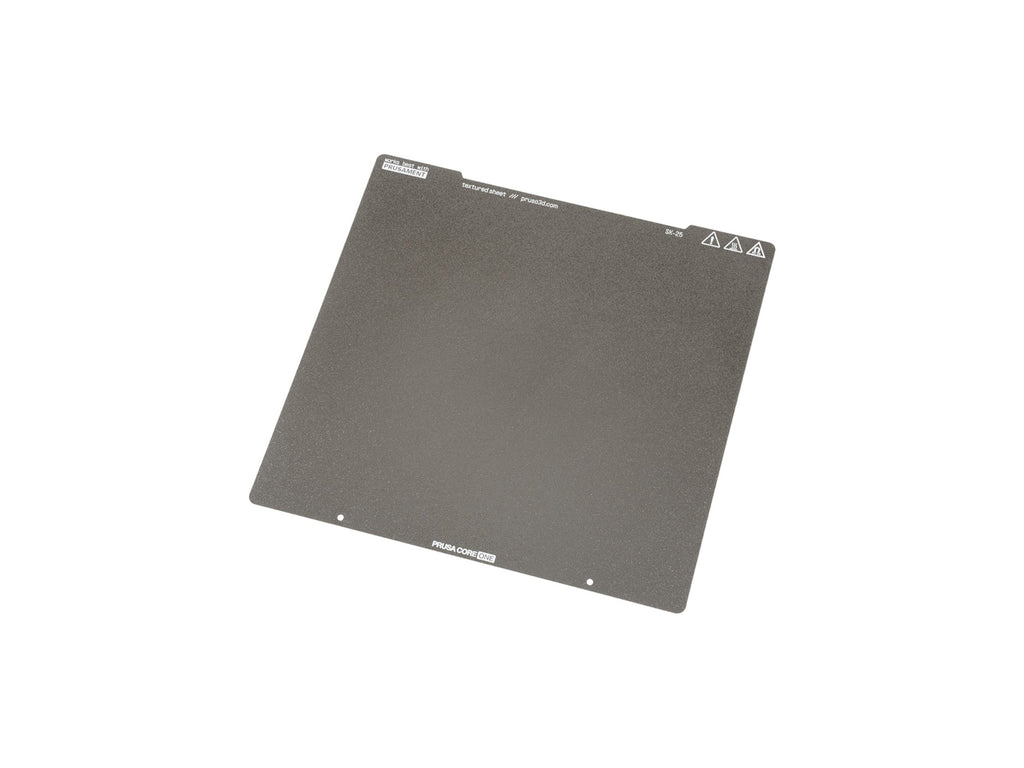

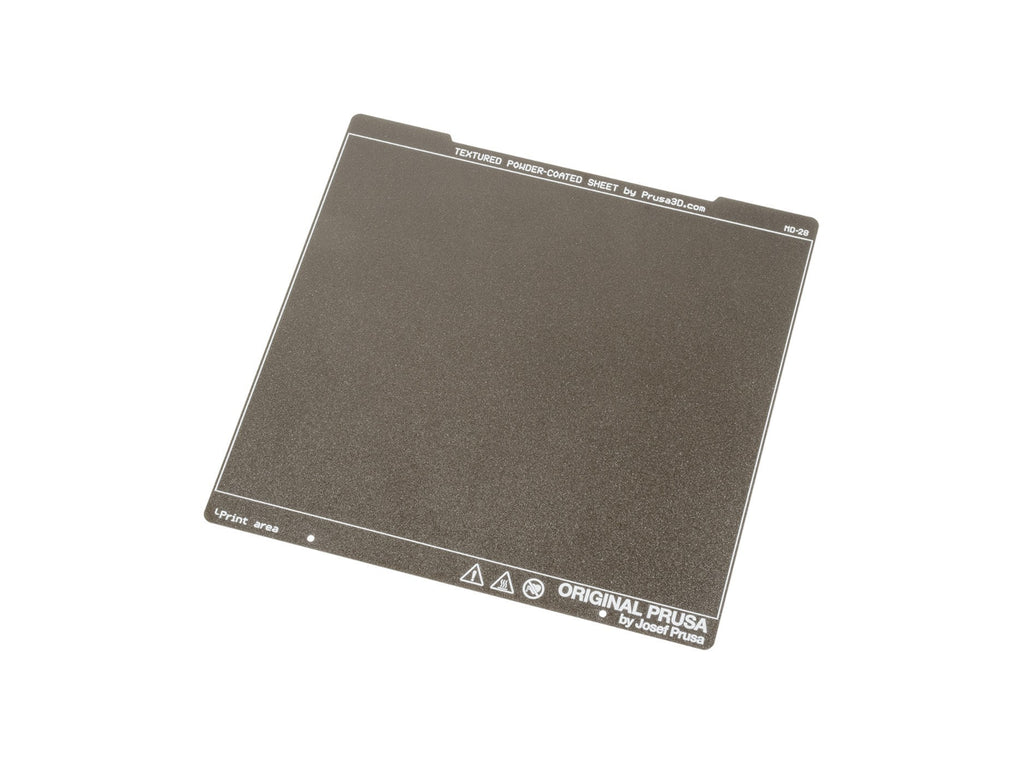

Textured Powder-coated Print Sheet [CORE One]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$55.99

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. Powder coating directly on metal makes it very hard to damage this build plate. If a heated nozzle crashed into it, the metal can dissipate the heat. Powder coating also gives the surface a distinct texture...

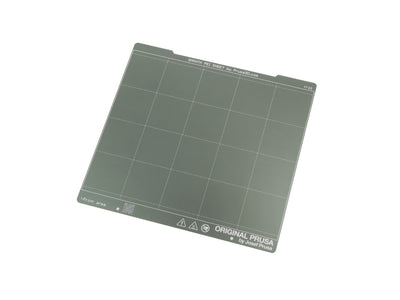

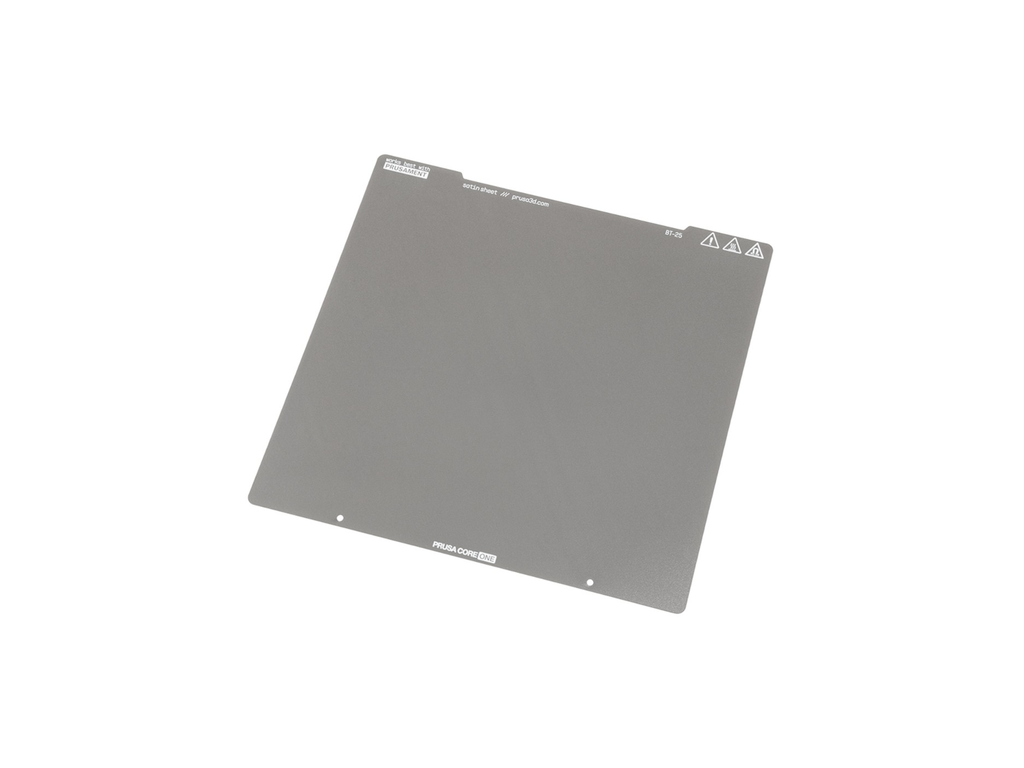

Satin Powder-coated Print Sheet [CORE One]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$65.99

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. The Satin sheet further expands our line-up of print sheets. In terms of printing properties, the Satin sheet sits between the smooth and textured variants. Its powder-coated surface with lightly textured m...

![PA Nylon Powder-coated Print Sheet [CORE One]](http://www.voxelfactory.com/cdn/shop/files/Prusa_CORE_one_PA_Nylon_Print_Sheet_Product_Picture_1024x.webp?v=1753730864)

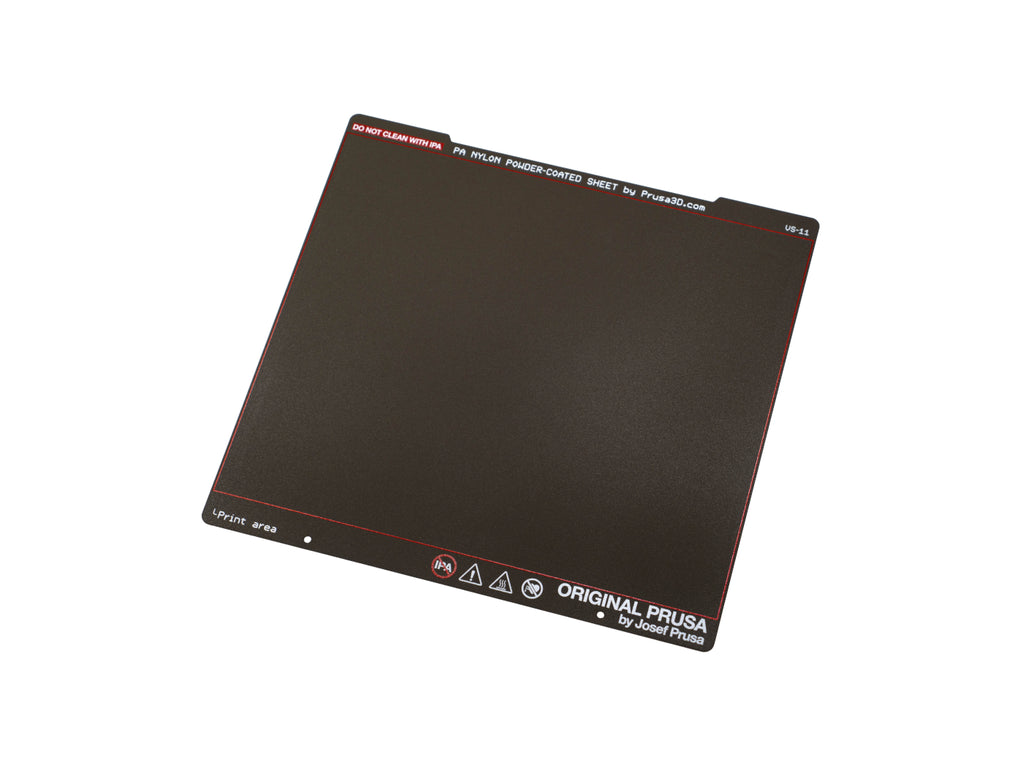

PA Nylon Powder-coated Print Sheet [CORE One]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$82.60

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets.This print sheet is specially designed to print polyamide-based filaments, especially the Prusament PA11 Carbon Fiber Black. The PA11-type materials have generally a lower adhesion on textured or satin print...

Satin Powder-coated Print Sheet [MK3|MK4]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$65.99

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. The Satin sheet further expands our line-up of print sheets. In terms of printing properties, the Satin sheet sits between the smooth and textured variants. Its powder-coated surface with lightly textured m...

Textured Powder-coated Print Sheet [MK3|MK4]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$55.99

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. Powder coating directly on metal makes it very hard to damage this build plate. If a heated nozzle crashed into it, the metal can dissipate the heat. Powder coating also gives the surface a distinct texture...

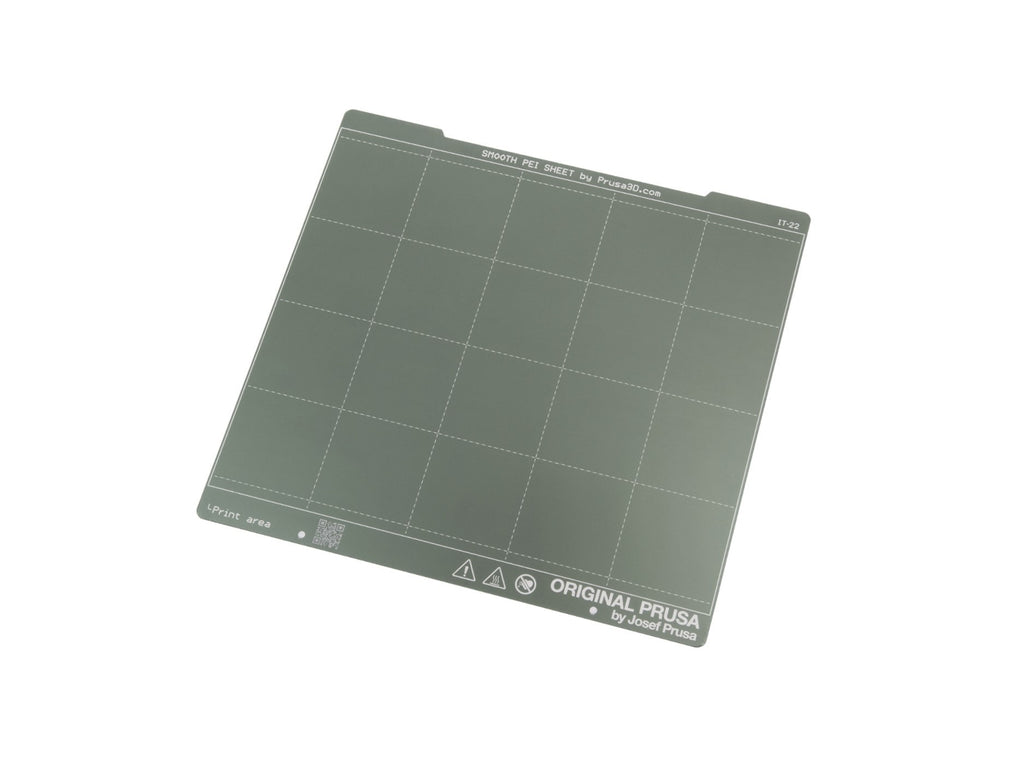

Smooth PEI Print sheet [MK3|MK4|CORE One]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$48.99

Update: The steel sheet color may differ from the product picture (black, gold, green, etc). The smooth PEI surface on the steel sheet, as well as all other properties, remain the very same for all color versions. The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets. Th...

PA Nylon Powder-coated Print Sheet [MK3|MK4]

- St-Hubert Store : Calculating...

- Burnaby Store : Calculating...

$82.60

OVERVIEW: The MK52 heatbed has embedded high Curie temperature magnets. These magnets are able to firmly hold removable spring steel sheets.This print sheet is specially designed to print polyamide-based filaments, especially the Prusament PA11 Carbon Fiber Black. The PA11-type materials have generally a lower adhesion on textured or satin print...

![PA Nylon Powder-coated Print Sheet [CORE One]](http://www.voxelfactory.com/cdn/shop/files/Prusa_CORE_one_PA_Nylon_Print_Sheet_Product_Picture_200x@2x.webp?v=1753730864)